Cool Tips About How To Build A Drum Shell

Beech wood is another hard dense wood that will produce very heavy drums.

How to build a drum shell. We then measure both the wrap and the shell, and cut the wrap to the correct size. The source for custom drum builder's worldwide, huge selection of custom drum parts, raw shells, hardware, coverings and drum heads at the lowest prices in the country!. Lay your shell on a flat surface with your center mark facing you, then grab your wrap also with your center mark facing you, and ever so.

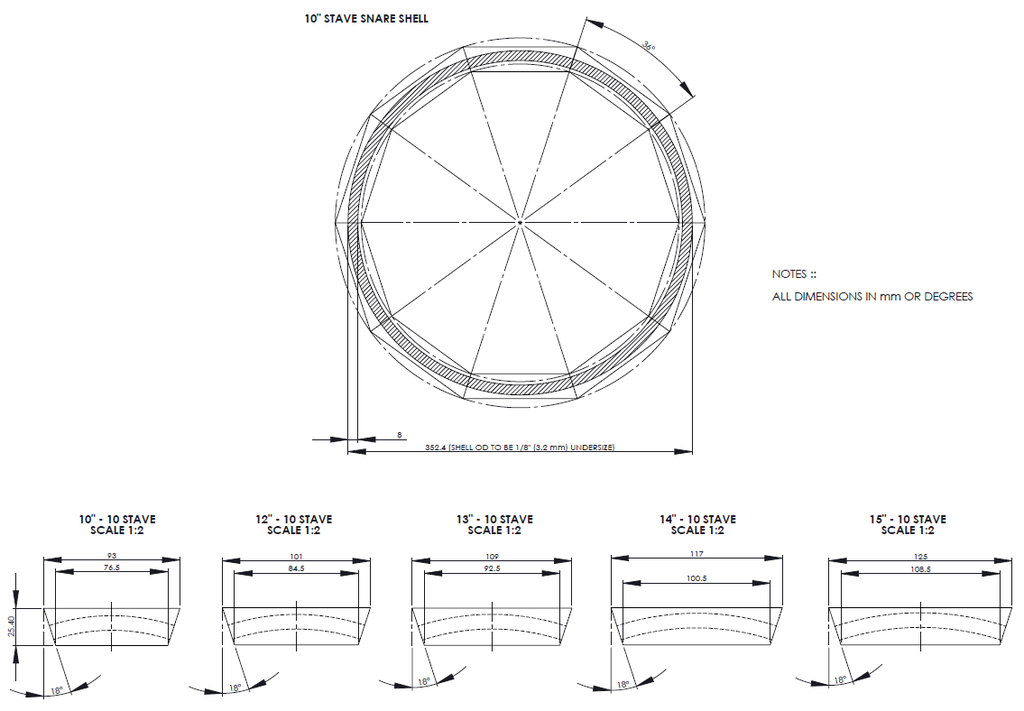

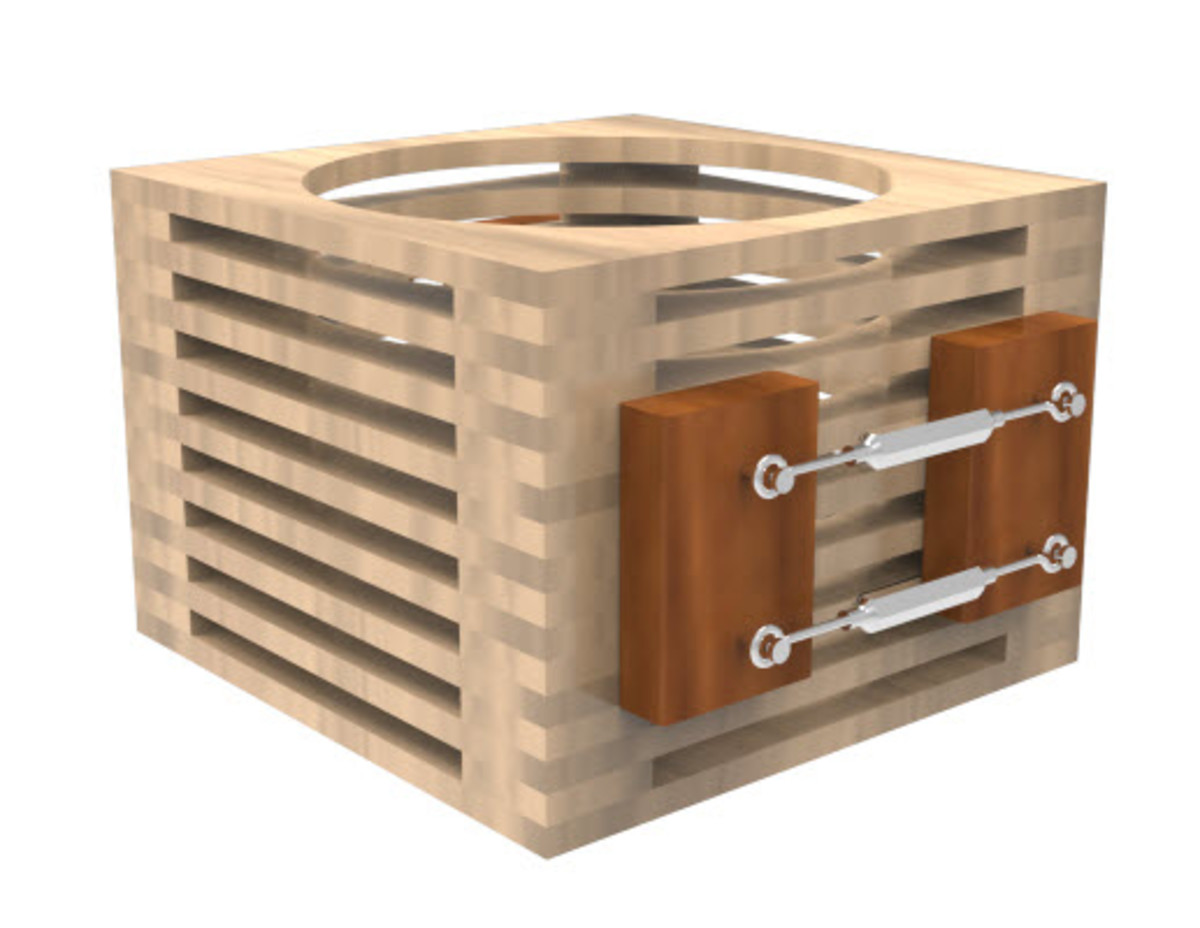

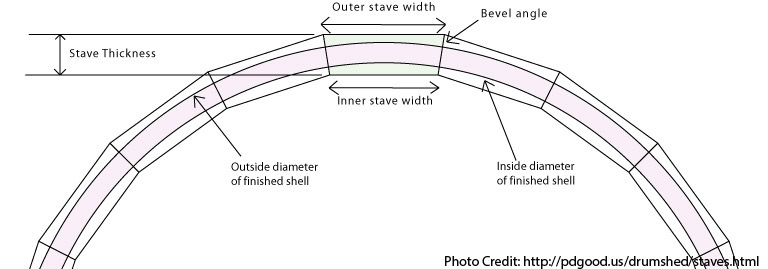

We're going to be making a 14 snare that is 6.5 deep and made from 10 staves (segments). To lay out the hardware, place a head and hoop on top of the drum, tape them down, then hang the tension screws down through the holes. To build a snare drum, first the ingredients are gathered and the shell of the drum is cut, sanded and coated.

Drum shells are the foundation of any drum kit. Therefore, it is important to choose your shells wisely. Bead about 1 pan, or 30 cm at a time and then smooth with scrap wood.

Both the wrap and shell need to be sanded a bit before. After that, pieces of cut veneer are moved through a glue press. The drawing above shows you some other options if you.

Use the excess collected in your scraper to fill holes that will not be. The first step is to pull and cut a raw shell to size. Holes are then drilled in specific locations for hardware and snare.

Precision drum company offers only the highest quality shells and has been. Slide all the tension rods to the far left or right of.